Sheet metal processing at Klockner Metals Austria

Sheet metal cutting

Kloeckner Metals possibilities

Our range of services extends from the production of small to large sheet metal blanks, which can be manufactured both as individual pieces and in series production. We also offer We also offer the option of combining sheet metal blanks with various other processing steps, including foiling, anodizing, powder coating and more, to meet your specific requirements. At your request, we can also add paper or cardboard interlayers to protect surfaces during transportation or storage.

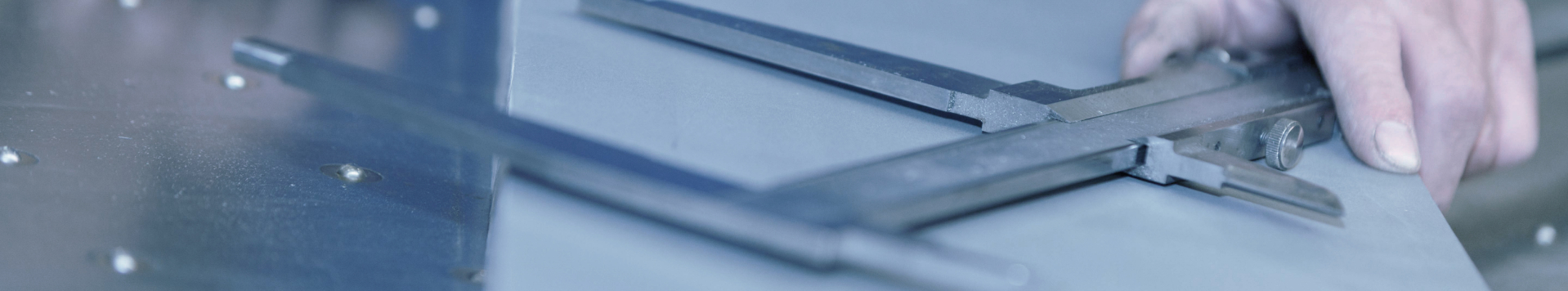

During the sawing process, the material is continuously wetted with a bio-emulsion or cooling lubricants to cool the sawing belt/saw blade.

Advantages of cut-to-size sheets at a glance:

Fast and reliable from small to large sheet metal blanks

Precise, low-burr cuts

Gentle material handling thanks to air cushion turntable

Special features of cut-to-size sheets

Our sheet metal cuts offer a wide range of dimensions and material thicknesses to meet your requirements.

The length of our sheet metal blanks ranges from a minimum of 30 mm to a maximum of 4300 mm, while the width ranges from a minimum of 8 mm to a maximum of 2100 mm. We can produce sheet metal blanks with material thicknesses from 0.2 to 150 mm with precision and low burr, whereby a cutting width of less than 5 mm is guaranteed.

Thanks to our clean-up function, we achieve a chip-free rate of 99.5%, which ensures clean and high-quality processing. In addition, we use special vacuum lifters for sheet metal processing to sheet metal processing to ensure both the safety of employees and the integrity of the material.

Slitting of coils

Narrower strips, known as rings or slit strips, are produced from a coil by slitting it lengthways.

Kloeckner Metals possibilities

This processing method, also known as splitting, guarantees excellent surface quality and uniform tension for all strips obtained after the slitting process. In certain applications, the cut edge can be used directly as a functional edge.

Advantages at a glance:

Fast and reliable from small to large sheet metal blanks

Precise, low-burr sheet metal cuts

Specialities

Narrow strips up to 3 mm thick and 10-1500 mm wide in aluminium, stainless steel and non-ferrous metal.

Cutting to length strips

The starting materials are strips from which sheets can be cut to standard and fixed lengths.

Kloeckner Metals possibilities

Optionally, the sheets can also be provided with various protective films.

Advantages at a glance:

Cross cutting to your desired size

With rounded or deburred edges possible

Sheet length up to 12,000 mm

Re-Coil

Our re-coil system rewinds large coils into small coils and fulfils individual customer requirements.

Kloeckner Metals possibilities

We rewind your aluminium or stainless steel coils from coils of approx. 1500 kg to "ready-to-build" coils of 100 to 200 kg.

Advantages of small coils at a glance:

Handy small coils of up to 200 kg, which are delivered directly to the construction site for further manual processing

Fast and reliable

Customised to your wishes